Microsilica and silicon metal powder are two very different products, in the actual use of the process, these two products are often confused, because they are inextricably linked.

Microsilica

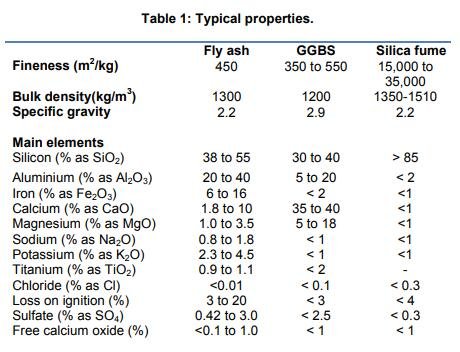

We usually say that Microsilica, also known as silica fume, microsilica powder, is in the production of silicon metal or ferroalloys in the process of recycling the soot, due to the high content of silica, very fine particles, high activity, in the concrete, refractory materials, rubber, paint and other industries have a wide range of applications.

Silicon Metal Powder

The main component of silicon metal powder is crystalline silicon (Si), which is initially in the form of lumps, and becomes powder after crushing or grinding, and is used in refractory materials and other industries.

Difference

- Silicon metal powder becomes powder because it is physically ground, and Microsilica is naturally formed during the production process.

- The chemical composition is very different. Microsilica is mainly silicon dioxide, and the main content of metallic silicon is SI elements.

- Silicon metal powders are usually inactive, while silica powders have volcanic ash activity.

- The color of metallic Microsilica is usually more stable, while the color of Microsilica varies from white to black.

- Microsilica are relatively versatile.

- Silicon metal powder is very expensive, several times more expensive than Microsilica.