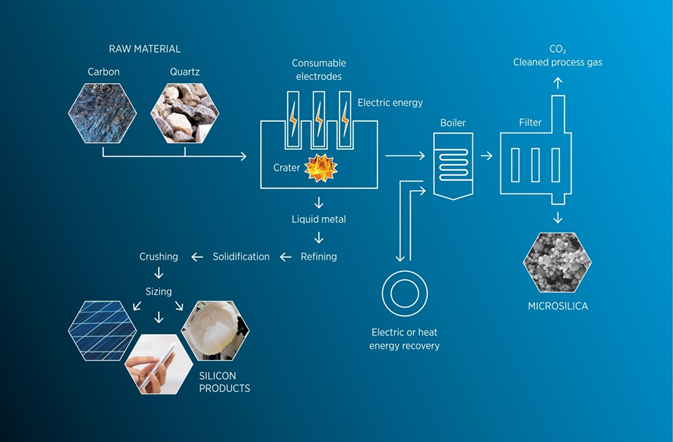

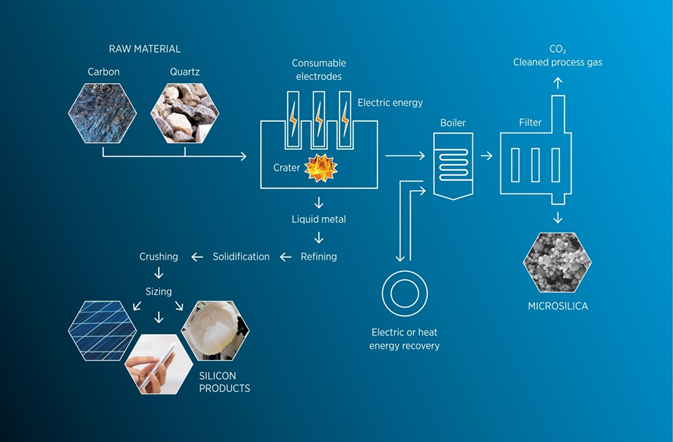

First, micro silica powder is collected.

When the equipment running resistance or time of the micro silicon powder manufacturer reaches the set value, the unloading process begins. The process of cleaning silica fume is realized by using the negative pressure of the front part of the main fan.

Then, the waste gas is purified. The flue gas from the EAF outlet is entered into the separation dust collector after being cooled down, and then through the duster, the micro silica fume manufacturer will gather the dust and the purified flue gas will be discharged into the atmosphere.

Finally, the silica fume manufacturers encrypt the micro silicon powder. After the collection of micro silicon powder transportation cost, therefore, after encryption, microspheres, not only save packaging and transportation costs, but also easy to load and unload.