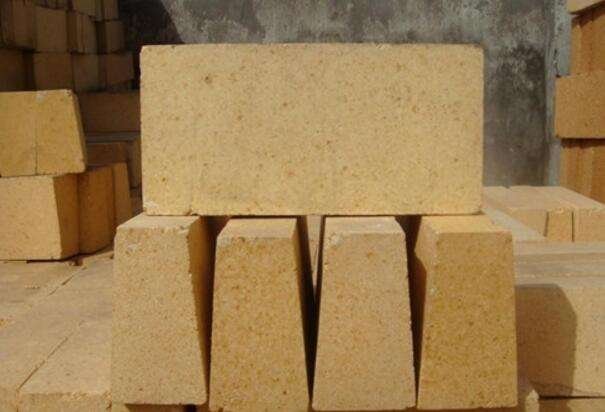

Refractory clay bricks ( chamotte refractory bricks )are alumina silicate bricks with the refractoriness of SK 32-34 and contain 35-40% alumina. The bricks are made from various raw material s of fire clay, calcined chamotte, soft clay. We manufacture chamotte bricks using thorough quality control. Shapes and properties depend unpon sevice conditions, becuase the bricks have low porosity, high strength, good resistance to thermal spalling and abrasion and to creep, they are applied for the linings of various incinerators, reheating furnaces etc.

Silica Fume in Refractory

1) The micro silica is as a raw material, commonly used in the refractory industry. It plays an important role to improve monolithic refractories.

2) Microsilica is filled in those gaps of which in the traditional refractories. Thus, it increases the bulk density and lowers the porosity, so that intensity can be increased abviously.

3) Micro silica contains strong activity to form colloidal particles in the water, and adding suitable dispersant to enhance liquidity, thereby improving performance casting.

4) Microsilica is easy to form -Si-OH in the water and has strong hydrophilicity and activity. It can enhance the cohesion of refractories, in the meantime, it also improves greatly the high temperature properties and extends the life of refractory products.

The effect of silica fume for refractory brick:

It is widely used in high performance refractory castables, silicon nitride sintering aids, ladle materials, self flow refractory castables, prefabricated parts, low or without cement castables and dry-wet spraying materials, due to high quality micro silica fume’s ultra-fine particle size, low water storage and high fluidity.

The specific performance and effect: can bond as refractory material and kiln materials, surfactant and mineralizer, is conducive to the improvement of refractory solid phase reaction and sintering driving force, reinforcement reaction speed and sintered density, conducive to the transformation of crystal stable structure, high temperature performance of the material.