Silica fume: the appearance is grey or gray – white powder, and the refractoriness is >1600℃.

Undensified Silica Fume (320-360kg/m³)

Densified Silica Fume (630-680 kg/m³)

The fineness of silica fume: the fineness of the silica fume less than 1um is over 80%, the average particle size is from 0.1 to 0.3um, and the specific surface area is 20 – 28 m2/g. The fineness and specific surface area are about 80-100 times of the cement and 50-70 times of the fly ash.

Particle morphology and mineral structure: during the formation process of silica fume, the amorphous phase is formed by the action of surface tension due to the effect of surface tension during the formation of phase change, and the surface is smooth. Some are aggregates with multiple spherical particles adhered together. It is a very high surface area and highly active volcanic ash. With silica fume, tiny spheroids can be lubricated.

Silica Fume Application:

1) Concrete or Shotcrete

– Increase its density and strength, improve the performance on its durability,

– impact resistance, corrosion resistance, anti-permeability and frost resistance etc

2) Refractory material & Ceramics material

– Greatly improve its density, strength and high temperature performance.

3) Cementitous Repair Products (Mortars & Grouts)

– Low permeability, increase resistance from chlorides, acids, nitrates and sulfate etc

4) Oil Well Grouting

– Increase durability and compressive strength, decrease permeability, better control of gas leakage

5) Concrete Tile, roofing & wallboard,panels

– Lightweight and improve the strength

6) Polymers & rubber product

7) other application, such as waterglass industry, thermal insulation material etc.

Features Characteristics

1).Appearance is as grey&white off.

2).High electrical resistivity

3).Low Permeability

4).Superior resistance to chemical attack from chlorides,acids and sulfates

5).Low chloride ion diffusion

6).High reactive Pozzolan

7).High temperature strength

8).Improved stability ingeothermal environment

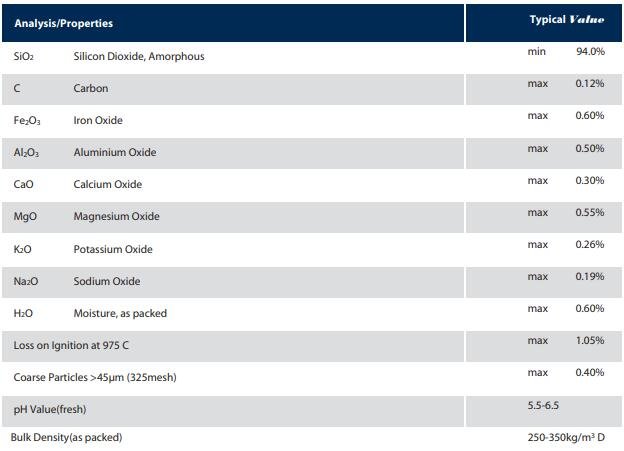

Technical parameter: